Supply Chain Modernization

A Supply Chain Built for Reliability and Performance

Sonepar is transforming its global supply chain to improve reliability and service

We are investing more than €2.5 billion to automate our logistics network and another €1 billion to strengthen our global digital platform. These investments support our goal to deliver more orders every day while reducing our environmental impact.

Warehouse automation that supports accurate and reliable order delivery

Sonepar uses warehouse automation and standardized processes to improve order accuracy and delivery reliability. Our goal is to ensure customers receive the products they need, when they need them.

Depending on the country, customers can access up to 100,000 products. Orders can be prepared in our central warehouses or branches and delivered to the required location.

Our logistics teams handle a range of delivery options, including scheduled deliveries, site deliveries, and click and collect. We work to provide practical solutions that match each project’s constraints.

We also support additional needs such as secured containers, kitting, and other specific delivery requests. Our teams help identify the most suitable option for each situation.

Our supply chain's transformation: automated warehouses

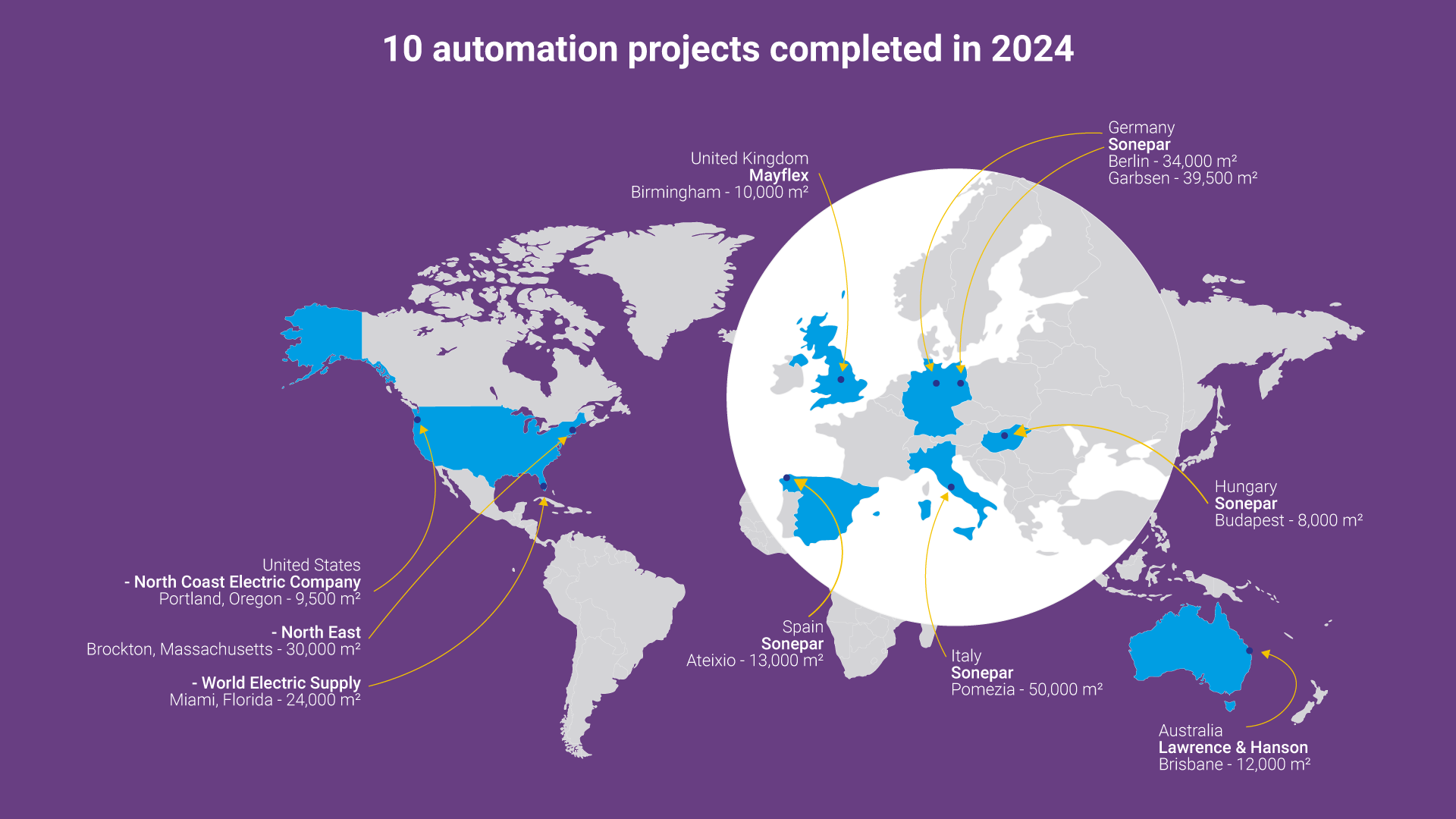

The transformation of Sonepar’s supply chain continues. In 2024, for the second year running, ten automation projects were successfully completed in our distribution centers across the world. We aim at reaching 60 automated distribution centers by 2028.

What is an automated distribution center?

An automated distribution center is a facility that uses technology and machinery to store, move and process products with limited human intervention. These systems help standardize tasks, increase reliability and support faster order handling.

Automated distribution centers often include:

- Automated Storage and Retrieval Systems (AS/RS). Robotic cranes or shuttles place and retrieve items from storage racks.

- Conveyor and sortation systems. These systems move products through the facility and route them to the correct areas.

- Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs). Driverless machines transport goods between work zones.

- Automated picking systems. Solutions such as robotic arms, goods‑to‑person stations or AI‑assisted vision systems support order picking.

- Warehouse Management Systems (WMS). Software that coordinates all automated processes, inventory data and order flows.

The aim of these technologies is to speed up operations, reduce errors, and increase overall throughput. They are especially useful in environments with high order volumes or short delivery deadlines.

Behind the scenes of automation in logistics

In our video series Behind the Counter, we visit distribution centers around the world where team members share valuable insights into their missions and experiences in logistics.

Reducing our environmental impact

Sonepar uses technology, data and standard processes to improve planning, preparation and delivery across its operations. These tools also help us identify ways to create safer workplaces, limit waste and reduce CO2 emissions throughout the supply chain, from suppliers to final delivery.

We apply several practical measures to support more sustainable operations. These include LEDs, photovoltaic solutions, reusable packaging, automated packaging sizing and the use of electric vehicles for specific delivery needs.

Our sites and processes are regularly assessed by independent organizations. Many locations in the Group have received certifications such as LEED, BREEAM‑excellent, Ecovadis and ISO.

As part of our Purpose, Sonepar aims by 2028 to use only packaging made from recycled materials and to recycle all products returned by customers.

In 2023, Cebeo, a Sonepar company, inaugurated its new automated distribution center in Blandain, Belgium. The 42,000 m² facility with a 50,000-product capacity displays ever-higher levels of warehouse and cable automation. The logistics center obtained the BREEAM-excellent certification, one of the highest sustainability ratings. It relies on solar energy with 7,000 solar panels and a water recovery and reuse system. All deliveries are made using reusable totes made of 100% recycled plastic, with no cardboard use.

In 2024, Sonepar inaugurated its newest distribution center in Padua, Italy. The logistics hub is the result of an investment of more than €50 million and is among the most advanced in Europe in its sector in terms of implemented technology and size (90,000 m²). It will serve more than 4,000 customers a day in Northern and Central Italy with deliveries within 24 hours, more than 55,000 items handled, 124 robots for storing and ordering small parts, automated shuttles and robot stacker cranes that feed automatic cable cutting machines, ergonomic boxing, ensuring a reduced environmental impact.

In 2024, Sonepar inaugurated a new automated distribution center in Berlin, Germany. The new facility, with 41,500m² of storage space and a 10,000m² cable yard, is equipped with advanced logistics technologies to streamline operations and boost resource efficiency. It holds space for 60,000 containers. This facility is a critical addition to Sonepar’s logistics network, enabling the company to meet growing demand with greater flexibility.

In 2025, Lawrence & Hanson (a Sonepar company) opened the doors to its new Brisbane Regional Fulfilment Centre (RFC), marking a major milestone in its Queensland operations. This facility represents a strategic step forward in enhancing service capabilities, improving efficiency, and supporting sustainable growth across the region.

Equipped with cutting-edge technology, including an Autostore system with 15 robots and 8 multifunction carousels, automated cable-cutting machines, and a vacuum panel lifter for solar, the site also features a 300-kW solar panel system, electric material handling equipment, and recycling partnerships reducing landfill waste.

Related content

Products and Solutions

Our offerings cover a wide range of specialties in the B2B distribution of cutting-edge electrical products and solutions.

Customers

We make life easier for our customers by anticipating and responding swiftly to their needs.

Services

As your partner, we offer you the benefit of our deep expertise so you can focus on your projects.